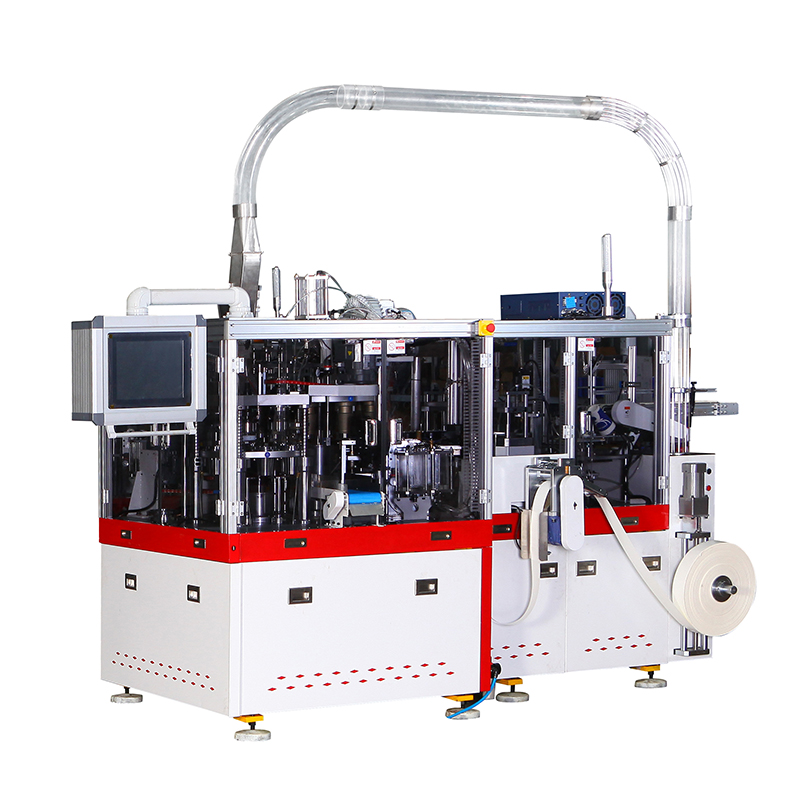

Manufacturer for Cup Plate Manufacturing Machine - FCM200 non-round container forming machine – HQ

Manufacturer for Cup Plate Manufacturing Machine - FCM200 non-round container forming machine – HQ Detail:

description

FCM200 is designed to produce non-round paper containers with stable production speed 50-80pcs/min. The shape can be rectangular, square, oval, non-round…etc.

Nowadays, more and more paper packaging been used for food packaging, soup container, salad bowls, take away containers, rectangular and square shape take away containers, not only for oriental food diet, but also for Western style food like salad, spaghetti, pasta, seafood, chicken wings…etc. Especially for rectangular containers, which are quite popular nowadays because it is stackable, recyclable, and distinctive shape. Comparing to normal traditional round shape containers, rectangular shape containers can save storage as well as transportation costs. Rectangular cup forming machine can make you stick out from crowd of competitors.

It’s working from paper blank pile, bottom punching work from the paper roll, with the both hot air heater and ultrasonic system for side sealing.

Specification of Machine

| Specification | FCM200 |

| Paper container size | Top length 90-175mm Top width 80-125mm Total height 45-137mm |

| Production speed | 50-80 pcs/min |

| Side sealing method | Hot air heating & ultrasonic |

| Bottom sealing method | Hot air heating |

| Rated power | 25KW |

| Air consumption (at 6kg/cm2) | 0.4 m³/min |

| Overall Dimension | L2,820mm x W1,450mm x H1,850mm |

| Machine net weight | 4,800 kg |

Finished Product Range

★ Top Length: 90 - 175mm

★ Top Width: 80 - 125mm

★ Total Height: 45-135mm

★ Other sizes upon request

Available paper

Single PE / PLA, Double PE / PLA, PE / Aluminum or water based biodegradable materials coated paper board

Competitive Advantage

TRANSMISSION:

❋ The mechanical transmission is mainly by gears to two longitudinal shafts. Structure is simple and effective, which makes repair and maintenance more convenient and time saving. The main motor’s output is from both sides of motor shaft, therefore the force transmission is balance.

❋ The open type indexing gear (turret 10 : turret 8 arrangement to make all function more reasonable). We choose IKO (CF20) heavy load pin roller bearing for indexing gear cam follower, oil and air pressure gauges, digital transmitters are use (Japan Panasonic).

HUMANIZED DESIGN STRUCTURE

❋ Front feed table is a double deck design which could prevent paper dust go into the main frame, which can extend the service life of gear oil inside machine frame.

❋ Folding wings、knurling wheel and brim rolling stations are adjustable above main table, no adjustment needed inside the main frame.

ELECTRICAL CONFIGURATION

❋ Electric control cabinet: The whole machine is controlled by PLC, we choose Mitsubishi high-end product. All motors are independent controlled by frequency invertors, these can adapt wide range of paper character and could get better rim rolling and bottom finishing effect.

❋ Heaters are using Leister, a well-know and reliable brand made in Swiss, ultrasonic for side seam supplemental.

❋ Lack of paper blank or paper missing and paper-jam etc., all these faults will display precisely in touch panel alarm window

Innovation and exploration into sustainable packaging is a top priority for us. HQ team is committed to meet your requirements as well as help you to create new market. One of our goals is to develop alternatives to replace traditional, non-renewable, or non-recyclable packaging.

To achieve this goal, we also offer the possibility to work together with us on the development of new products; from brainstorming to drawings and from sample production through to realization.

Product detail pictures:

Related Product Guide:

We know that we only thrive if we can guarantee our combined price tag competiveness and top quality advantageous at the same time for Manufacturer for Cup Plate Manufacturing Machine - FCM200 non-round container forming machine – HQ , The product will supply to all over the world, such as: Australia, Rio de Janeiro, Moldova, Aiming to grow to be by far the most experienced supplier within this sector in Uganda, we keep researching on the creating procedure and raising the high quality of our principal merchandise. Till now, the merchandise list has been updated on a regular basis and attracted customers from around the globe. In depth data can be obtained in our web page and you'll be served with good quality consultant service by our after-sale team. They're about to make it possible for you to get complete acknowledge about our things and make a satisfied negotiation. Small business check out to our factory in Uganda can also be welcome at any time. Hope to obtain your inquiries to get a happy co-operation.

We have been looking for a professional and responsible supplier, and now we find it.