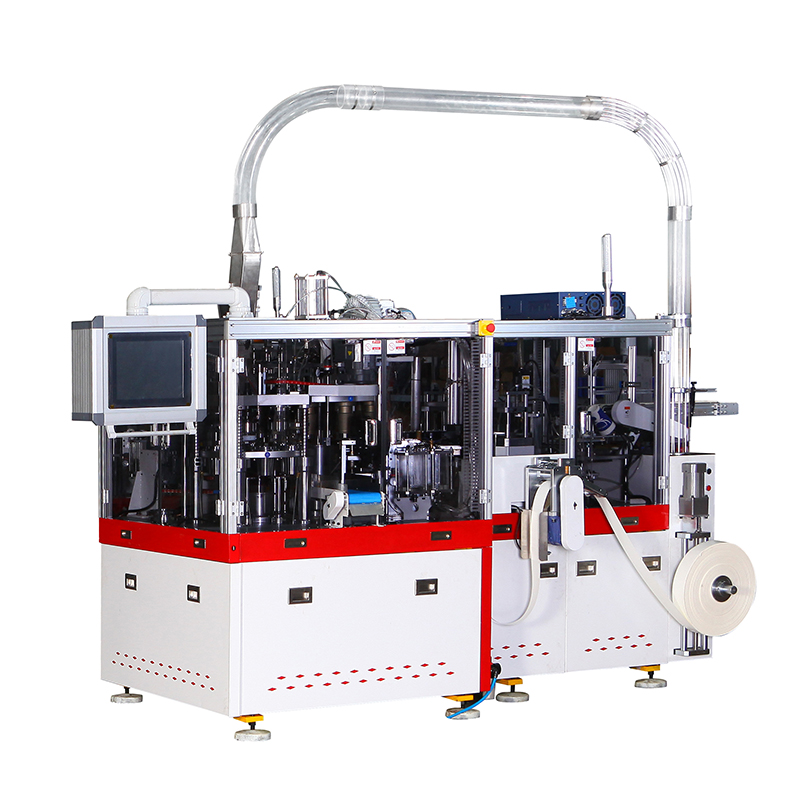

OEM Manufacturer Oval Cup Machine - SM100 ripple double wall cup forming machine – HQ

OEM Manufacturer Oval Cup Machine - SM100 ripple double wall cup forming machine – HQ Detail:

description

SM100 is designed to produce ripple wall cups with stable production speed 120-150pcs/min. It’s working from paper blank pile, with ultrasonic system or hot melt gluing for side sealing.

Ripple wall cup gets more and more popular because its unique hold feeling, anti-skid heat-resistance feature and comparing to normal hollow type double wall cup, which occupy more space during storage and transportation because of stacking height, ripple cup could be a good option.

Specification of Machine

| Specification | SM100 |

| Paper cup size of manufacture | 2oz ~ 16oz |

| Production speed | 120-150 pcs/min |

| Side sealing method | Ultrasonic / Hot melt gluing |

| Rated power | 21KW |

| Air consumption (at 6kg/cm2) | 0.4 m³/min |

| Overall Dimension | L2,820mm x W1,300mm x H1,850mm |

| Machine net weight | 4,200 kg |

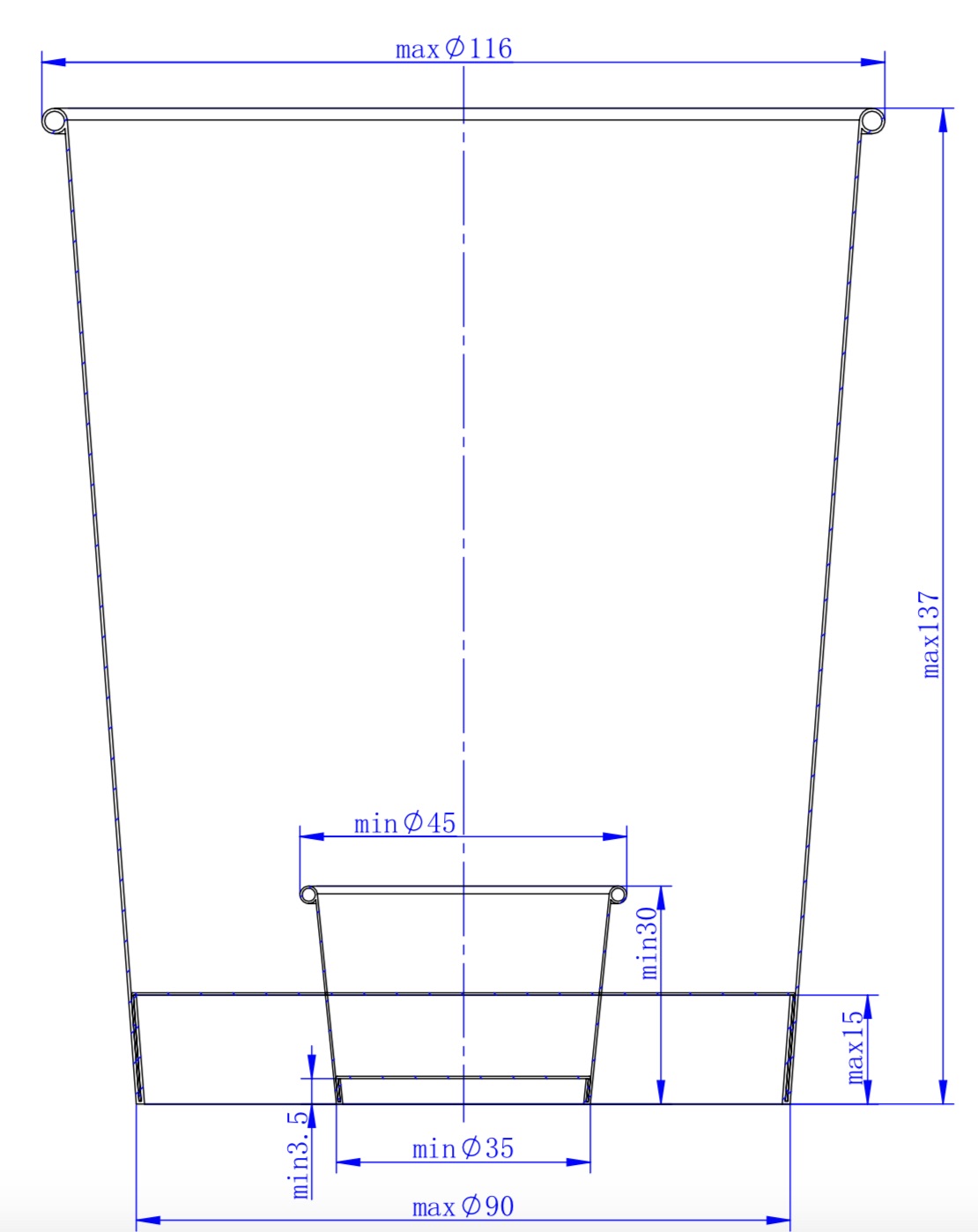

Finished Product Range

★ Top Diameter: 45 - 105mm

★ Bottom Diameter: 35 - 78mm

★ Total Height: maximum 137mm

★ Other sizes upon request

Available paper

Coated or un-coated paper board

Competitive Advantage

❋ The feed table is a double deck design to prevent paper dust go into the main frame.

❋ The mechanical transmission is mainly by gears to two longitudinal shafts. The main motor’s output is from both sides of motor shaft, therefore the force transmission is balance.

❋ The open type indexing gear (turret 10 : turret 8 arrangement to make all function more reasonable). We choose IKO (CF20) heavy load pin roller bearing for indexing gear cam follower, oil and air pressure gauges, digital transmitters are use (Japan Panasonic).

❋ Electric control cabinet: The whole machine is controlled by PLC, we choose Japan Mitsubishi high-end product. All motors are independent controlled by frequency invertors, these can adapt wide range of paper character.

❋ Paper low level or paper missing and paper-jam etc., all these faults will display precisely in touch panel alarm window

One unique feature of HQ SM100 sleeve machine is that it is designed to produce ripple cup, normal type of double wall cup, hybrid cup with inner plastic cup and out-layer paper sleeve wrapped. Besides that, SM100 machine can be converted to a 2-32oz paper cup forming machine, which is more flexible for production range and easier to shift to paper cup production when needed.

Product detail pictures:

Related Product Guide:

Assume full responsibility to satisfy all needs of our clients; achieve continual advancements by endorsing the expansion of our purchasers; turn into the final permanent cooperative partner of clientele and maximize the interests of clients for OEM Manufacturer Oval Cup Machine - SM100 ripple double wall cup forming machine – HQ , The product will supply to all over the world, such as: Peru, Mexico, Pakistan, With more than 9 years of experience and a professional team, we have exported our products to many countries and regions all over the world. We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,