OEM Supply Built In Bean To Cup Coffee Machine - CM100 paper cup forming machine – HQ

OEM Supply Built In Bean To Cup Coffee Machine - CM100 paper cup forming machine – HQ Detail:

Specification of Machine

| Specification | CM100 |

| Standard Machine Configuration | Extended magazine for auto paper blank feedingFinished cup counting and nesting tableOne set of forming mold for one cup size |

| OptionalEquipment | In-line cup inspection system |

| Paper cup size of manufacture | 2oz ~ 32oz |

| Production speed | 120-150 pcs/min |

| Side sealing method | Leisterhot air heating & ultrasonic |

| Bottom sealing method | Leisterhot air heating |

| Rated power | 21KW |

| Air consumption (at 6kg/cm2) | 0.4 m³/min |

| Overall Dimension | L2,820mm x W1,300mm x H1,850mm |

| Machine net weight | 4,200 kg |

Finished Product Range

★ Top Diameter: 45 - 105mm

★ Bottom Diameter: 35 - 78mm

★ Total Height: maximum 137mm

★ Other sizes upon request

Available paper

Single PE / PLA, Double PE / PLA, PE / Aluminum or water-based barrier coated paper board

Competitive Advantage

REASONABLE TRANSMISSION DESIGN

❋ The mechanical transmission is mainly by gears to two longitudinal shafts. The main motor’s output is from both sides of motor shaft, therefore the force transmission is balance.

❋ Transmission structure is reasonable, simplicity and effective, leaves enough room for repair and maintenance.

❋ The open type indexing gear (turret 10 : turret 8 arrangement to make all function more reasonable). We choose IKO (CF20) heavy load pin roller bearing for indexing gear cam follower, oil and air pressure gauges, digital transmitters are use (Japan Panasonic).

HUMANIZED STRUCTURE DESIGN

❋ The feed table is a double deck design to prevent paper dust go into the main frame. Table is designed with reasonable width, which is more convenient for maintenance.

❋ The second turret equipped with 8 working stations. So additional functions such as third rim rolling station (for better rim rolling) or grooving station can be realized.

❋ Folding wings、knurling wheel and brim rolling stations are adjustable above main table, no adjustment needed inside the main frame so that the work is much easier and time saving.

ELECTRICAL COMPONENTS CONFIGURATION

❋ Electric control cabinet: The whole machine is controlled by PLC, we choose Japan Mitsubishi high-end product. All motors are independent controlled by frequency invertors, these can adapt wider range of paper character.

❋ Heaters are using Leister, which is well-known brand made in Swiss, ultrasonic for side seam supplemental.

❋ Paper low level or paper missing and paper-jam etc., all these faults will display precisely in touch panel alarm window.

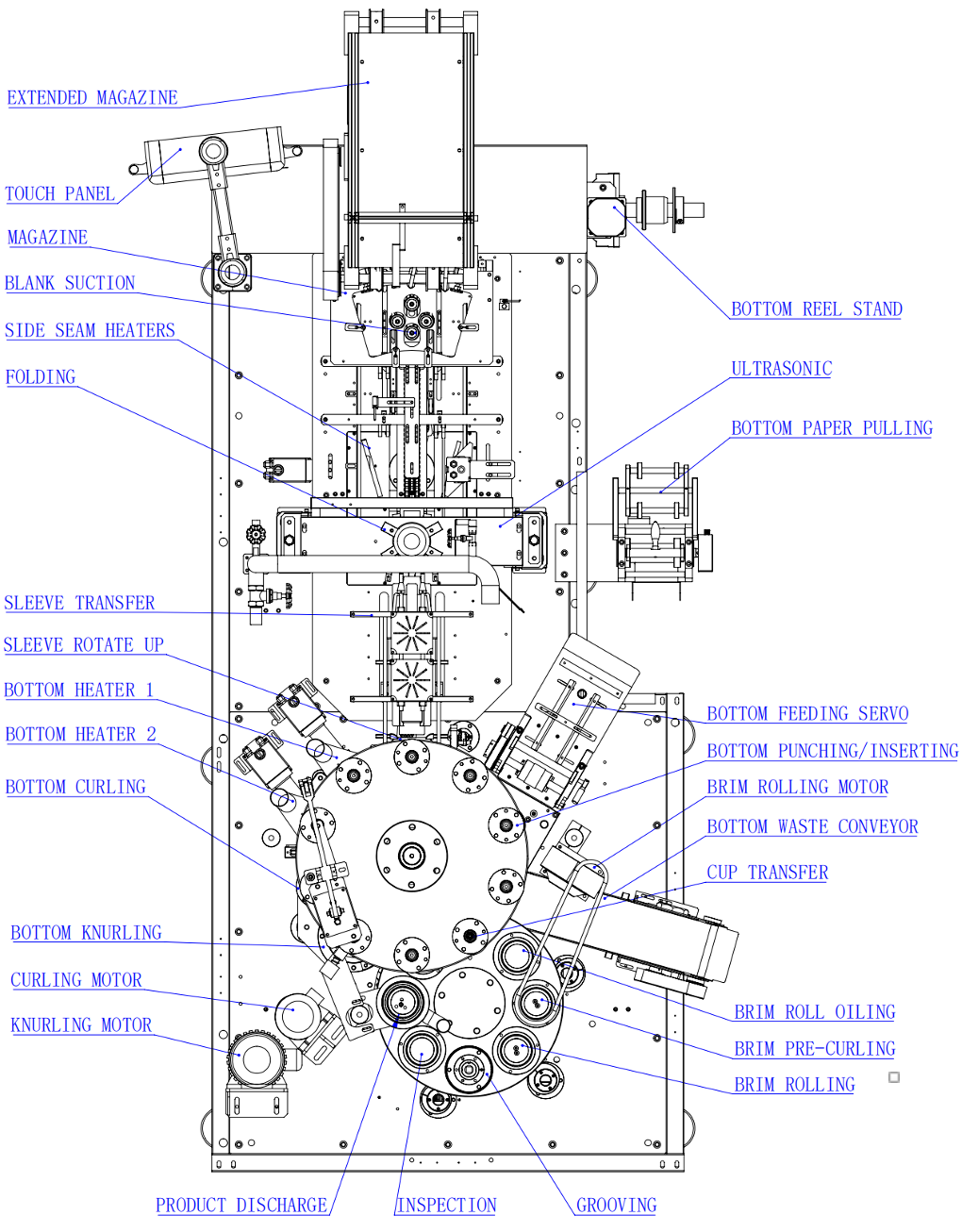

Machine Working Steps

Paper blanks feeding → side-seam heating → folding & sealing → cup sleeve transfer → bottom forming & inserting → male mandrel → bottom heating1 → bottom heating 2 → bottom oiling → bottom curling → bottom knurling → semi-product transfer → cup rim oiling → rim curling 1 → cup rim curling 2 → discharge to counting & piling

video

Product detail pictures:

Related Product Guide:

We insist on offering high quality production with good business concept, honest sales and the best and fast service. it will bring you not only the high quality product and huge profit, but the most significant is to occupy the endless market for OEM Supply Built In Bean To Cup Coffee Machine - CM100 paper cup forming machine – HQ , The product will supply to all over the world, such as: Honduras, Riyadh, Kenya, To get more information about us as well as see all our products, please visit our website. To get more information please feel free to let us know. Thank you very much and wish your business always be great!

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

Top